Product Demonstrations

-

A case study on controlling foreign body contamination – with Freaks of Nature

BST Detectable Products & Freaks of Nature discuss the importance of controlling foreign body contamination Freaks of Nature, based in Ossett (West Yorkshire), launched their plant based desserts with Tesco in April 2017 to huge success. Their delicious desserts, which include ‘Mango Fandango’, ‘Cocoa Loco’ and the new ‘Strawberry Blonde’ and ‘Choc & Awe’ Cheesecakes Read More -

A case study on the development and use of new food grade detectable ID tags - for FoodPro Manufacturing Ltd

FoodPro Manufacturing Ltd, part of Browns food group, are a leading ready meal manufacturer with over 30 years’ experience and boast clients such as ASDA, Morrison’s, Iceland, Tesco, Lidl, Aldi, NISA, P&H, Spar & Birdseye. Their range of products include frozen traditional, Indian, Italian and Chinese meals, as well as deserts. Their state of the Read More -

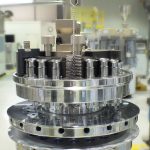

A case study on the development and use of bespoke detectable brushes - for PTK-GB

PTK are a leading global manufacturer of pharmaceutical machinery, with stylish designs, robust structures, state of the art technology and high performance: rotary tablet presses, automatic capsule filling machines, coating machines and high speed mixers. Gareth Gregg, Manager at PTK GB first met BST Detectable Products at the 2015 PPMA show, where he saw the Read More -

A case study on bespoke Detectapen® branding - for Metal Detection Services Ltd

MDS are the CEIA UK distributor for industrial metal detection equipment in the food, pharmaceutical and textile industries. They supply and service metal detection systems, bespoke conveyor systems, data management systems and even offer a metal detector rental service. After experiencing problems with their existing metal detectable pens, MDS turned to BST for a higher Read More -

BST DetectaPen Shatter Resistant Testing

A brief video demonstrating the shatter resistant J800 DetectaPen. BST J800 Detectapens are industry renowned as the highest quality choice of stationery for use in hygiene critical food processing environments. Every feature of the pen is designed with the food industry in mind, resulting in a truly unique set of properties designed to minimise contamination Read More