The new BST Eco v2.0 DetectaPen boasts all the same properties as the original Eco but with an all new sleek mat design for ultimate writing comfort and the new BST Trace-It DetectaPen is the ideal affordable, retractable, detectable pen!

Introducing Innovative Nitrile Gloves:

A Breakthrough for Safety and Comfort

In a stride towards enhanced safety and user comfort, a groundbreaking line of nitrile gloves has emerged, setting new standards in the realm of personal protective equipment (PPE). Engineered with precision and care, these gloves offer a unique blend of qualities that cater to a diverse range of users, while ensuring the highest level of performance in various industries.

Lightweight and Durable Design

Crafted to be both lightweight and durable, these nitrile gloves redefine the expectations of disposable PPE. Users can now experience unparalleled ease of movement, minimizing fatigue during extended wear. The advanced nitrile material not only guarantees exceptional durability but also ensures a prolonged lifespan, making these gloves an optimal choice for applications that demand reliability and longevity.

Latex Allergy-Friendly

Addressing a common concern among users, these nitrile gloves are an ideal solution for individuals with latex allergies. The gloves provide a safe and comfortable alternative, eliminating the risk of allergic reactions.

Enhanced Chemical Resistance

One of the standout features of these nitrile gloves is their superior resistance to chemicals. Designed to withstand a variety of substances, these gloves offer an added layer of protection in environments where chemical exposure is a consideration.

Optimal Grip and Ambidextrous Design

Featuring textured fingers that provide an exceptional grip, these powder-free gloves empower users with enhanced dexterity and control. Moreover, their ambidextrous design ensures a universal fit, eliminating the hassle of distinguishing between left and right gloves.

Food Contact Approved and Metal Detectable

These gloves have received the coveted food contact approval, underscoring their suitability for use in food-related industries. Additionally, their metal detectability by in-line detection systems adds another layer of safety and quality control, ensuring the prevention of foreign body contamination. While the performance of detection may vary based on specific factors such as the type of food being inspected and equipment specifications, these gloves consistently uphold a high standard of quality assurance.

Compliance with International Standards

Rest easy knowing that these nitrile gloves adhere to rigorous international quality standards. This compliance serves as a testament to their exceptional design and manufacturing, offering users peace of mind and confidence in their choice of protective gear.

In a world where safety and comfort are paramount, these innovative nitrile gloves deliver an unprecedented level of reliability. Whether in a bustling food processing facility or a precision-oriented laboratory, these gloves are poised to revolutionise the way we approach personal protective equipment, setting a new precedent for excellence in safety, comfort, and performance.

In 1985, Brian S Teasdale (BST) started a family business right here, in Britain. The company initially focused on providing engineering supplies to UK bakeries, before inventing, designing, and manufacturing the concept of metal detectable products and the world’s first plastic metal detectable pen.

BST are proud to be the original pioneers in metal detectable plastic and rubber technology and are the driving force in the UK combatting the issue of plastic contamination in food production worldwide; Specialising in metal detectable, x-ray visible, shatter resistant, antimicrobial, food safe, BRC compliant products, utilised across all food sectors to reduce the risk of foreign body contamination.

In 2013, BST Detectable Products (the original detectable products company) officially became members of Made In Britain, and today over 85% of products stocked and sold by BST are Made in Britain! Displaying the Made in Britain mark shows a level of commitment to sustainability and safety as well as being recognised as a symbol of high quality.

BST supply detectable products to not only the food and drink industry, but the pharmaceutical, petfood, cosmetics, and textiles industries too. BST products are high quality, ergonomic, and a wide range of the products are antimicrobial and so are also suited to environments of high-risk cross infection such as medical areas, reception areas, open plan offices, and call centres.

Detectable products are now an integral part of food safety and HACCP procedures throughout the world. As new regulations and legislations have highlighted the necessity for detectable, food safe products in the food industry, it is becoming increasingly important to show due diligence in the prevention of plastic and rubber contamination. BST focus on producing high quality detectable products, less susceptible to wear and therefore less likely to end up contaminating food in production. Should a BST detectable item break or be dropped into food production, fragments as small as 5mm³ can be detected by metal detection or x-ray inspection systems and automatically be rejected from the production line.

BST undertake extensive research in developing new products to address contamination risks; Working with a vast network of specialised British manufacturers, many of whom have become strategic partners with BST over generations. Through designing and manufacturing new detectable products to continuously updating existing lines, BST strive to provide a dynamic detectable solution to every contamination risk.

BST understand what it means to have a global reach. With an expanding worldwide network of distribution partners, BST detectable products are currently available in over 70 countries.

Through celebrating partnerships with local British suppliers as well as worldwide distributors, through striving to innovate and build quality into every aspect of the business, from design and manufacture to logistics and support, BST embodies British culture.

BST are proud to be British.

There are different types of detectability as well as different levels of detectability within those types. There are metal detectable products, made by incorporating metal additives into plastic and rubber compounds. Then there are x-ray visible products, made by incorporating high density additives. Finally there are visually detectable products, this can be achieved by using brightly coloured compounds (usually blue but also other colours for traceability and coordination, to prevent cross contamination of allergens as well as foreign bodies), this is so that the coloured plastic or rubber stands out against the product. A product which incorporates all three will have the highest chance of being detected.

Now, although higher detectability can have a negative effect on the structural integrity of the product, due to the additives being added, there are materials which have been formulated to combat this issue. It is possible and preferable to have a high functioning material with greater detectability. Another thing to consider is the worst case scenario of an item becoming a contaminant, a shatter resistant product with no small internal parts will be easier detected.

Researching into the products can be incredibly beneficial in this area, data sheets will provide you with evidence and results from product testing so that you know exactly what each product is capable of.

When working with or around food products, it makes sense for your tools, which are intended to come into direct contact with the food products, to be food contact approved.

However, as legislation is changing to incorporate more and more aspects of the food production process, it would be wise to create an environment which houses solely food contact approved loose items.

When an item is food contact approved this means that it is suitable to come into direct contact with food, is suitable for its intended use, and will not create a food safety hazard. There are a number of accreditations which can be attributed to a product through testing such as FDA and EU approvals.

Although it is not the intended purpose of an item of stationery such as a pen or clipboard to come into contact with the food product, its shows due diligence in the prevention of food safety hazards to ensure that these, and other loose items are also food contact approved.

A fabulous, detectable, food contact approved item is one thing, but it also has to work as intended! Functionality, really, is the most important aspect of any given product, it needs to work within its specific environment. What would be the point of an all singing, all dancing detectable product, if it immediately stops working or becomes fragile and brittle in more extreme work environments?

Pens, for example, are known to be less reliable in cold, damp, or greasy conditions. If these environmental conditions apply to you and your workplace, make sure to look for pens with pressurised refills, these will continue to work in all conditions and also allow you to write on vertical surfaces or even upside down if needs be.

There is a detectable product out there specifically designed for every environment, from markers and fine liners to gel or pressurised refills, and if you can’t find exactly what you’re looking for, don’t be afraid to enquire. Suppliers will be grateful for your input and some will be able to provide bespoke options made from materials better suited to your environment, so you don’t have to settle for ‘good enough’.

Finally, there is the personal design of a product. The convenience of a product can sometimes make all the difference in day-to-day working life. If an item of stationery can be attached to a lanyard, if a tool can be hung or displayed on a shadow board, if an item has an anti-slip or anti-roll design, these things have the potential to have a huge impact on your organisation and carrying out of general procedures.

And the big question: is the item comfortable to hold and use? Using the same items day after day can have a toll on your body and general comfort if they are not ergonomically designed. Choosing an item which feels nicer, which requires less strain or grip, will reduce fatigue as well as reducing wear on the item.

With BST you don’t need to worry about the basics, we have that covered. A wide range of our products are metal detectable, x-ray visible, anti-microbial, food contact approved, and feature no small internal or external parts. Our pens offer impressive write-out lengths which means your pen will work well and keep working, and all products have an ergonomic design to ensure maximum ease and comfort during use. With a product for every environment and condition, why go anywhere else?

BST have supplied vacuum depanner belts since 1985 and have been asked on numerous occasions why it is that we don’t have these items available to be purchased online. The answer is that 1. Depanner belts are bespoke items made to exact specifications, so we require more communication to ensure the customer receives the perfect product. And 2. Depanner belt prices vary so much that it would be impossible to list all possibilities on our website.

Naturally, the follow up question to this is “Why are depanner belt prices so varied?”. Well, this is what we will be addressing to our best ability in this article.

The obvious factor affecting pricing would be the size of the product. It makes sense that a larger product would cost more than a smaller product due to the amount of material and time required to assemble. BST vacuum depanner belts are manufactured using food grade three ply fabric backing, with a white FDA food grade PVC coated front (bread facing side). Our belts are 5mm thick and joined with a superior finger over finger spliced bi-directional join. The belts can operate in temperatures up to 110°C, are long lasting, chemical resistant, strong, durable and can be designed to your exact size specifications down to 0.01mm.

From there, you can have the belt supplied blank (with the required holes) or fitted with our BST detectable retaining clips and suction cups. A larger belt does not always mean a greater number of cups and clips. A smaller belt could have a greater number of cups tightly condensed per row and therefore require a greater number, increasing the cost, just as a larger belt could have fewer cups per row, and so reducing the cost. Not only will the amount of cups and clips affect the cost, but so will the type of cups and clips chosen.

BST offer a range of detectable suction cups both hard and soft which vary in size and purpose. Should you require help selecting the ideal cup for your application, our team are always on hand to discuss your requirements and help provide the perfect detectable solution. This also applies to retaining clips as we offer both double and single hexagonal retaining clips fitted to our belts.

The final thing that affects the depanner belt cost is the additional features such as trackers. Some systems require a tracker fitted to the belt to ensure the smooth running of the depanning process. This again, is more material and time and therefore increases the cost of the overall belt.

So as you can see, there are simply too many variables which contribute to costs to be able to provide our depanner belts solely through our website. In the interest of providing each of our customers with the highest quality, perfect detectable solution, we feel it is necessary to have in-depth communication when planning a bespoke vacuum depanner belt.

If you have any questions about this or any other bespoke product from BST, please don’t hesitate to call us on 01302 775208 or email your enquiry to [email protected]. You can also click on the thumbnails above to read more about BST depanner belts and download specification documents.

BST Detectable Products take our Environmental Policy very seriously. It is important to us to be as ecological as possible, whilst still providing customers with quality products that fulfil their needs.

Fortunately, one of BST’s primary objectives when designing and developing a product is durability. When a product is reliable and durable, it lasts longer, and the longer a product lasts, the less often energy and raw materials are required to produce a replacement. Good for our customers, good for us, good for the environment.

During the manufacturing process it is important to monitor product waste such as offcuts of material and excess parts. We monitor our processes and improve them where possible to use resources efficiently to their full potential and limit waste. Through ongoing research and education as well as self-regulation, we are able to conserve energy and monitor every stage of the supply chain in order to reduce our negative impact on the environment to the lowest possible levels.

The obvious environmentally friendly move is to reduce, reuse, and recycle and that’s exactly what BST does. We reduce their need for and use of ‘virgin’ materials when packing our products by reusing boxes and packaging that come in from suppliers. Why waste a perfectly good box? Even when reusing materials, we aim to keep packaging to a minimum while also ensuring that the products are sufficiently protected as to not become damaged in transit. We also encourage our customers to continue the good work by providing pen recycling boxes which they can fill with their empty pens and return to us. We will then recycle those into new pen bodies or grind them down and use the material to mould into a new product.

Any waste that we do create is taken away by licenced waste removers.

On top of all this, day to day office life at BST is also as environmentally friendly as possible with the use of energy efficient lighting and technology wherever possible and extensive research into which business vehicles will create the least impact on the environment.

In today’s world, going green is the only responsible option. After all, in destroying the planet we are only destroying ourselves.

There are three main groups of metallic contaminants that can be picked up by a metal detector. Ferrous, nonferrous, and stainless steel. Ferrous contaminants are the easiest to detect as they are electrically conductive and magnetic. Non-ferrous contaminants are not magnetic, however they offer good conductivity. The most difficult to detect are stainless steel contaminants as they tend to be non-magnetic and possess poor conductivity, meaning that metal detectors are able to reject a smaller size of ferrous material than that of stainless steel.

The newest multi-spectrum metal detectors can achieve very high levels of sensitivity. In order to maintain the level of detection required, regular service and testing of any detection system in use should be in place and documented by a professional. An x-ray inspection system is required to detect non-metallic foreign body contaminants such as stone, bone, glass, and ceramics.

An x-ray inspection system works by passing low energy x-rays (gamma radiation) through the product, which then passes through the detection array. The differences between the amount of energy absorbed by the product and the contaminant is then calculated and analysed by the computer.

Through a calibration sequence the system will have learnt the profile of the product passing through, meaning that it knows what a good product looks like as well as the different variations that may occur in a product with no contamination. Therefore, it can detect any anomalies and remove contaminated or otherwise unsuitable product. X-ray systems can also capture and store an image (radiograph) of where the contaminant has been found so that it can be easily investigated.

meaning that it knows what a good product looks like as well as the different variations that may occur in a product with no contamination. Therefore, it can detect any anomalies and remove contaminated or otherwise unsuitable product. X-ray systems can also capture and store an image (radiograph) of where the contaminant has been found so that it can be easily investigated.

Whilst an x-ray system can detect ferrous, non-ferrous, and stainless steel contaminants they can also detect stone, bone, glass, and ceramics as these are typically a higher, contrasting density to most food products. However, X-ray inspection systems may have trouble detecting items with a similar density to the product such as fruit stones, insects, low-density plastics, stalks, string, and wood.

Through HACCP analysis, audit, incident, or by accident - you may become aware of an item that represents a foreign body contamination risk. If that item is essential to your process and it is not possible to remove it - it should be considered whether that item can be made from detectable materials; but it is important to be aware that not all detectable materials are the same.

The first detectable products were used in food production in the late 1980's and featured iron filings embedded within, or stuck to, high risk items in order to trigger the end of line metal detector should they inadvertently be introduced to the product. Today’s approach is much more scientific, refined, regulated, and researched. The ferromagnetic additives used have an ultra-fine particle size and carry full FDA and EU food safety approvals. Their dispersion in carrier polymers and rubbers should be homogeneous and at a level that does not compromise the mechanical integrity of the material.

Ferromagnetic additives are used to make a plastic or rubber detectable for the purpose of metal detectability, but food safe ultra-dense additives must be used to achieve good x-ray contrast performance. When these additives are introduced to polymers at the correct ratios, x-ray inspection systems can detect fragments as small as 3mmس.

In 2009 BST were the world's first company to develop a high performance dual detectable polymer. This is a plastic compound that contains the appropriate levels of both ferromagnetic and high density additives to trigger metal detection and x-ray inspection systems, whilst still functioning as a high performance polymer. Dual detectable products represent a huge step forward in food safety as they are safe for use in factories that may use metal detection on one product line and x-ray inspection on another, therefore saving money.

As school’s sports days kick off all over the country, we at BST thought it would be a fun team building exercise to use some of our own products and create ourselves our own little BST Sports Day!

You can check out all of the pictures and footage on our social media channels but for now, here's a small snippet to give you all a smile! >>

You can check out all of the pictures and footage on our social media channels but for now, here's a small snippet to give you all a smile! >>

We embraced some healthy competition and a good amount of team work as we kicked off our first event, the classic Egg and Spoon Race featuring the BST Detectable Sampling Spoon. (view post here)

Our detectable sampling spoon is food safe and non-toxic, ideal for sampling liquids as well as smaller piece solids (like tiny eggs!).

Next up, the teams tackled the Shot Put Throw featuring the BST Detectable Suction Cups and Storage Trays. (view post here)

BST detectable storage trays are manufactured using xdetect®, BST's flagship and industry renowned metal detectable and x-ray visible plastic. This plastic is designed entirely with food safety in mind. On a normal day, our BST suction cups, with their metal detectable properties and extensive food contact approvals, are used as a fast and effective method of extracting bakery products from oven pans on a moving conveyor belt.

The competition heated up as each team took on the ‘Beanbag’ Balance featuring the BST Detectable Jugs. (view post here)

Our range of detectable jugs come in a variety of sizes from 500ml to 2L. Whether you’re scooping, pouring, measuring, or balancing, we will certainly have a jug to suit your needs.

Finally, our competitors worked together to dominate the Three-Legged Race featuring the BST Detectable Cable Tie. (view post here)

Our metal detectable cable ties are strong, durable, and highly resistant to corrosion. Cable ties are handy, convenient, cost effective, strong, and can be used in a multitude of applications (although we wouldn’t recommend using them for a three-legged race).

Check out our LinkedIn, Facebook, Instagram, Twitter and TikTok posts!

Plastics are always changing, improving, adapting with greater and more expansive mechanical properties to prove greater durability and more desirable results. Some plastics are even available with modifications to even more accurately suit a given application such as increased strength or heat resistance. It is, then, increasingly difficult to know which plastic to choose over another, and with so many options available now, it can even be hard to know the difference between one plastic and another.

It is my hope that the following comparisons between different plastics intended for similar uses will help to clear things up a little and aid in your decision making process.

Aviation, Automotive, Telecom - PEEK vs PPSU

When it comes to high-performance thermoplastics, both PEEK (Polyetheretherketone) and PPSU (Polyphenylsulfone) offer excellent thermal properties and dimensional stability. These plastics have much in common and are often used in similar applications, however, each one possesses unique properties that the other does not and so it is important to understand the differences in order to choose the right plastic for your application.

PEEK provides greater compressive and tensile strength than PPSU as PPSU is prone to stress-cracking if not properly treated and maintained throughout the process. However, PPSU has a greater resistance to indentation than PEEK and would be a better choice for water and electrical resistance.

Medical - PPSU vs POM

POM (Polyoxymethylene) is often used in medical and healthcare applications due to its resistance to cleaning disinfectants and solvents. That said, POM does manage to retain its properties and appearance for the first few hundred sterilisations, but after that it fails in appearance and then continues to lose its properties from there. This is why PPSU (Polyphenylsulfone) has started to be considered as a replacement for POM as it has proven to be a higher performance material. After repetitive sterilisation, PPSU has proven to retain its appearance and dimensional stability much longer than POM.

Mechanical Parts - POM vs PA

PA (Polyamide) is commonly referred to by the more popularised name ‘nylons’. These titles cover a range of material types as it can be paired and altered to provide a wide range of properties. It is for this reason that PA (or Nylon) is commonly used to make mechanical parts. PA is highly resistant to wear and is able to maintain its properties at higher temperatures than other plastics. Unfortunately though, it does have a tendency to absorb moisture over time.

This is where POM (Polyoxymethylene) comes in. POM is also widely used to produce high precision parts as an alternative to metals as it provides good dimensional stability. Both these materials have good sliding properties, low wear, good temperature range but POM also has the added bonus of low moisture absorption. However, POM does have a tendency to degrade with alkali and chlorine.

High Voltage - PA vs PBT

PA (Polyamide) and PBT (Polybutylene Terephthalate) are both used in high-voltage environments. They both have good chemical resistance, are strong, and have good wear resistance; so which is actually better suited to the application?

Well, initially you may think that PA is the superior plastic, as in dry conditions it shows better values than PBT across the board. This is largely due to the fact that both extruded and cast Nylons (PA) can be modified through fillers to enhance its properties. However, due to the higher moisture absorption rate, PA loses its dimensional stability, bringing it down to the level of PBT statistics.

The low moisture absorption rate of PBT means that it is able to retain its properties even in hot, moist environments which would suggest that perhaps PBT is more suitable for use in humid, high-voltage environments than PA.

Food Industry

When it comes to using plastic materials in food industry applications, there are many factors worth considering. Depending on where and how you require the material to function, properties such as Strength, Elasticity, Chemical Resistance, Heat Resistance, Moisture Absorption, Food Contact Compliance, and Detectability will play a vital role in choosing the correct plastic for the job.

If, for the sake of this document, we look at the two food industry specific attributes (Compliance and Detectability) all of these materials would come highly recommended. PPSU (Polyphenylsulfone) is FDA compliant and the rest are both FDA and EU compliant. PPSU (Polyphenylsulfone) is X-Ray Visible and PA (Polyamide) is Metal Detectable. POM (Polybutylene Terephthalate) and PBT (Polybutylene Terephthalate) are both Metal Detectable and X-Ray Visible, and PEEK (Polyetheretherketone) can be modified to be dual detectable too.

It then comes down to the environment and specific role of the plastic to narrow down which would be better suited than another.

Summary

It is clear that all these materials bring something to the table.

In regards to strength, you can’t really go wrong with any of the materials mentioned above, the only outlier would potentially be PA (Polyamide) as it loses its strength under certain conditions such as in hot or damp environments.

If you require elasticity from your plastics, PEEK (Polyetheretherketone) and PA (Polyamide) have good elasticity and therefore provide greater compressive strength. Whereas PPSU (Polyphenylsulfone), POM (Polybutylene Terephthalate), and PBT (Polybutylene Terephthalate) do not and are therefore better suited for wet environments and electrical/high voltage applications.

Although POM is known to degrade with alkali and chlorine, the remaining plastics all exhibit good chemical resistance.

As has been previously mentioned, the properties of PA quickly degrade when exposed to heat. POM has a better functional range of -40° to +140° and the rest have excellent heat resistance.

Finally, moisture can cause an issue for PEEK and more so for PA but PPSU, POM, and PBT all have a low moisture absorption rate. This means they are less likely to lose their properties or degrade in moist or wet environments.

If you have any questions or queries about specific needs and requirements or questions about the materials in general, please don’t hesitate to contact our sales team for more information on 01302 775208 or email us at [email protected].

Bibliography

BST are now official stockists of the

detectable range from Vikan

BST stock a wide variety of food preparation items from shovels to scrapers, knives to buckets, and much more. Now our stocked items also include Vikan’s new range of detectable utensils which have been specially designed for use in hygiene critical areas and perfectly complement our existing high quality range of detectable products. Each item in the Vikan range features single mould construction to eliminate bacteria traps and improve hygiene.

Bespoke shadow boards are also available and can be designed to be fixed to a wall or as a mobile unit, coming in a variety of colours and layouts to suit all requirements.

Click here to view more information or get in touch with our sales team on 01302 775208 or email [email protected].

Visit our website or get in touch to find out more about our newly stocked scoops, scrapers, shovels, paddle mixers, and more.

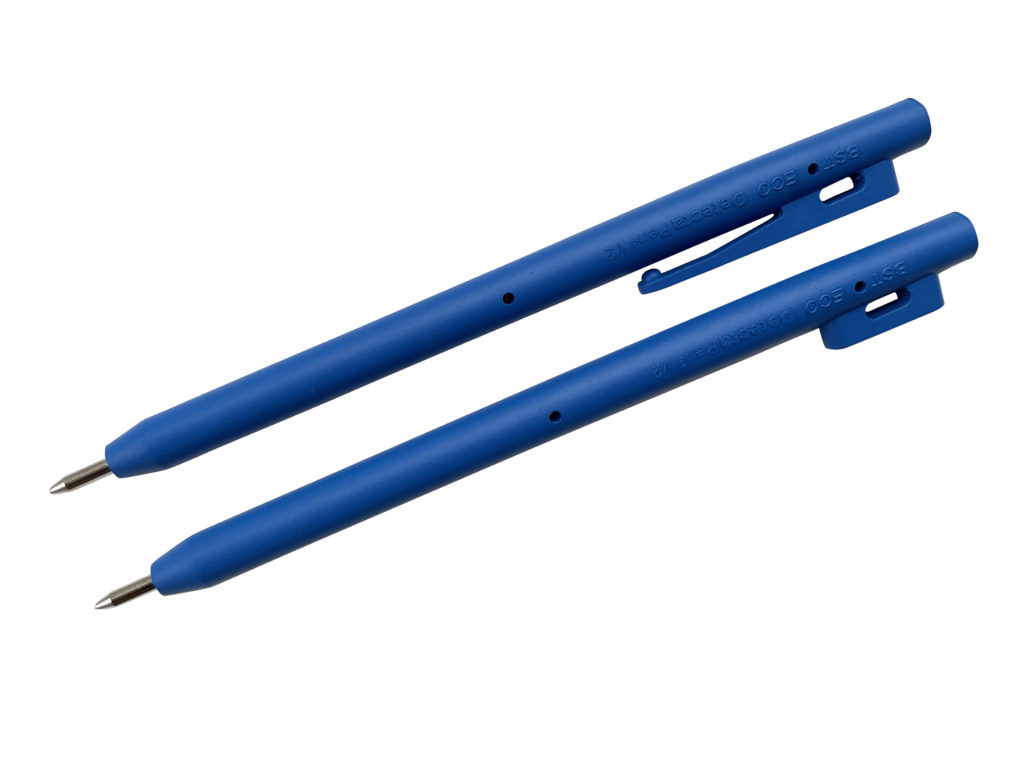

The new BST Eco v2.0 DetectaPen boasts all the same properties as the original Eco but with an all new sleek mat design for ultimate writing comfort and the new BST Trace-It DetectaPen is the ideal affordable, retractable, detectable pen!

The New Eco V2.0

The New Eco V2.0

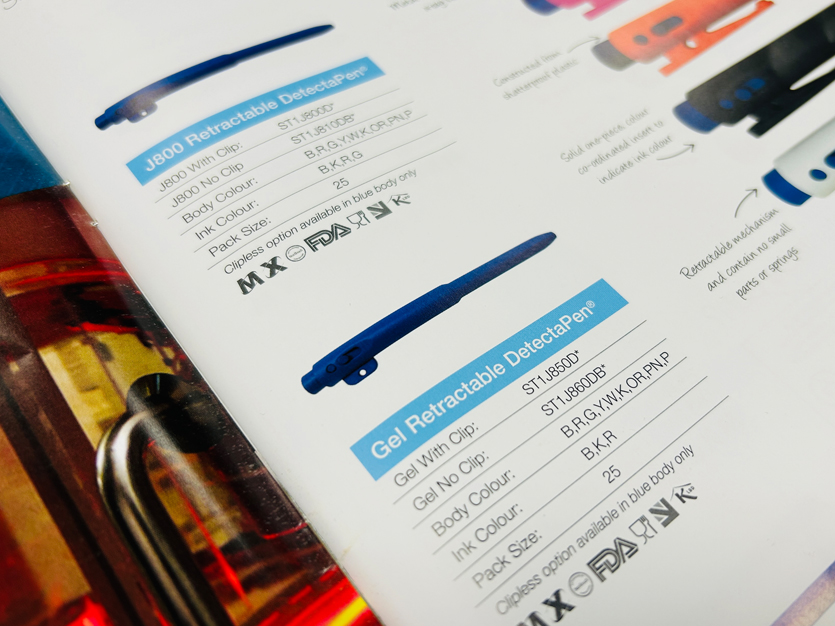

Check out the new look of the Eco V2.0! They feature a one piece metal detectable and x-ray visible plastic body made from our specially formulated xdetect Polypropylene compound. The beautifully simple design is comprised of only two main components, the pen body and the ink cartridge, both of which are dual detectable.

They boast all the same properties as the original Eco and all of the other pens in the BST DetectaPen range, including FDA and EU food contact approvals, they are shatter resistant, lanyard compatible, incorporate silver ion antibacterial technology, and we are proud to say ‘Made in Britain’. The Eco V2.0 is currently available in blue and red bodies with a choice of inks.

The New Trace-It

The New Trace-It

This brand new economical alternative to our premium pens features a metal detectable and x-ray visible plastic body and insert which is made from our specially formulated xdetect Polypropylene compound. With a blue body for visual identification and black and blue ink options, as well as clipped and looped models available, these pens are designed to be the perfect addition to your food production areas.

They boast the same properties as other pens in the BST range, including FDA and EU food contact approvals, made from strong, durable, chemical resistant and shatter resistant material, lanyard compatible, and we are proud to say ‘Made in Britain’.