A case study on the development and use of bespoke detectable brushes - for PTK-GB

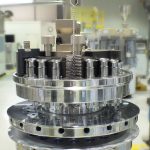

PTK are a leading global manufacturer of pharmaceutical machinery, with stylish designs, robust structures, state of the art technology and high performance: rotary tablet presses, automatic capsule filling machines, coating machines and high speed mixers. Gareth Gregg, Manager at PTK GB first met BST Detectable Products at the 2015 PPMA show, where he saw the potential of using metal detectable products to improve the safety of his machinery and his clients maintenance operations.

As well other bespoke developments, PTK GB specified to BST their requirement for shorter, more practical tube cleaning brushes that would be the ideal tool for cleaning their tablet presses, whilst offering additional protection from stray bristles causing contamination. As well as the FDA approved bristles being highly secure, they are also metal detectable, meaning that any stray bristle would be reliably detected and rejected by in line metal detection systems, which are already used on a routine basis to protect against metallic contamination of tablets.

PTK GB made the following statement about their experience with BST Detectable Products:

“While selecting the best quality tools for our machinery’s tool kit’s we had the idea to apply metal & x-ray detectable items to our range to optimise end product safety. BST were an easy choice of partner, as we share a focus on both quality and innovation, which are pre-requisites in the Pharmaceutical and Nutraceutical Environment in which we operate. Their energy and expertise continues to assist us in ground breaking new innovations relating to our niche working environment.

PTK-GB have more than 25 years’ experience with the supply of Tablet Compression and Encapsulation machinery, as well as machine parts and Compression Tooling. The range offered by BST very much complements our existing product ranges and helps us in striving for higher levels of Good Manufacturing Practice.”

Gareth Gregg ~ Manager ~ PTK-GB

Written by Will Anderson BSc (Hons), Head of Product Development & Marketing at BST Detectable Products